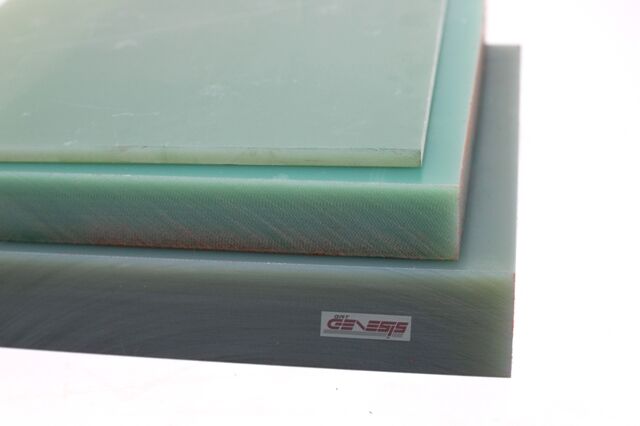

Paper, cotton, and glass cloth are combined with various resin systems and laminated under heat and pressure to produce materials with excellent mechanical and electrical properties.

During this process, the application of heat and pressure triggers a chemical polymerization reaction, transforming the layered structure into a solid, cohesive mass. This transformation is irreversible under normal conditions; once cured, the material cannot be re-softened by reheating—except under special circumstances.

This irreversible change in the resin’s structure creates an infusible, insoluble material, known as a thermosetting plastic.

Each grade offers a unique combination of mechanical, electrical, thermal, and chemical properties, making these materials highly versatile and ideal for a wide range of critical applications.

Popular Applications:

- Electrical Control + Test Panels

- Switchgear Mounting

- Phase Barriers, Bus Supports

- Terminal Boards and Mounting Strips

- Arc Chutes and Barriers

- Electrode Insulation + Supports

- Bus Tube Insulation

- Wave Solder Pallets + hardware

- Washers, Spacers, Shims

- Bushings, Standoffs, Stops

- Terminal Blocks

- Motor Slot Wedges, Topsticks, End Laminations

- Clamps, Dividers, Lids, Caps

- Wear Strips, Friction Plates, Seals

- Gears, Actuators, Cams,

- Guides, Rails, Supports, Ribs

- Mounting Brackets

- Fuse Tubes

- Core Winding Tubes

- Mounting Panels

For more details click here to visit our Material Specification Library Page (Size Charts and Spec Sheets).